Novolac systems provide outstanding chemical, thermal shock, and impact resistance for industrial and institutional applications.

Novolac

Superior chemical resistant, 100% solids Novolac epoxy systems with optional texture coat

System Overview

Innovacoatings Novolac systems are suited for industrial and institutional applications. Compared to standard epoxies, Novolac epoxy systems provide outstanding chemical resistance, along with higher operating temperature and impact resistance.

Use Area:

Kitchens, bakeries, food processing, animal research, chemical storage rooms, battery charging areas

Type:

Novolac Epoxy

Features:

- Thin film to 1/8” system

- May be used for recoating existing systems

- Higher operating temperature

- Optional texture

Benefits:

- Customizable cost savings

- Improve chemical and impact resistance

- Appropriate around ovens, areas of higher constant temperature

- Improves safety and chemical resistance

Selected Physical Properties

| Product | Description | Test Method | Results |

|---|---|---|---|

| 70704/70705 Novolac | Compressive Strength | ASTM D695 | 10,000 psi |

| 70704/70705 Novolac | Shore D | ASTM D2240 | 84 |

| 70704/70705 Novolac | Taber Abrasion | ASTM D4060 | 40 mg/10,000 CS-17 |

| 70704/70705 Novolac | Chemical Resistance | See Chemical Resistance Chart | |

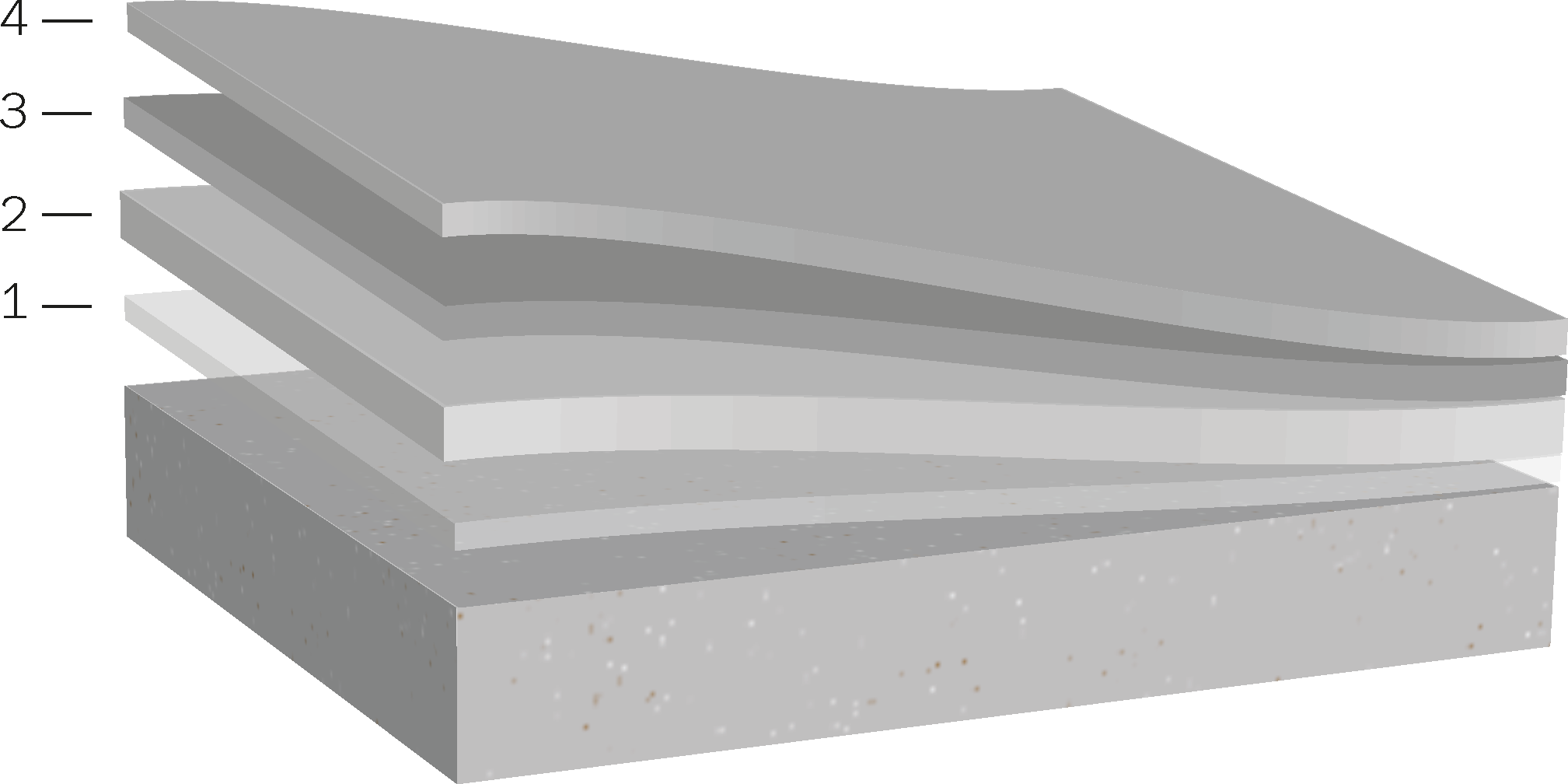

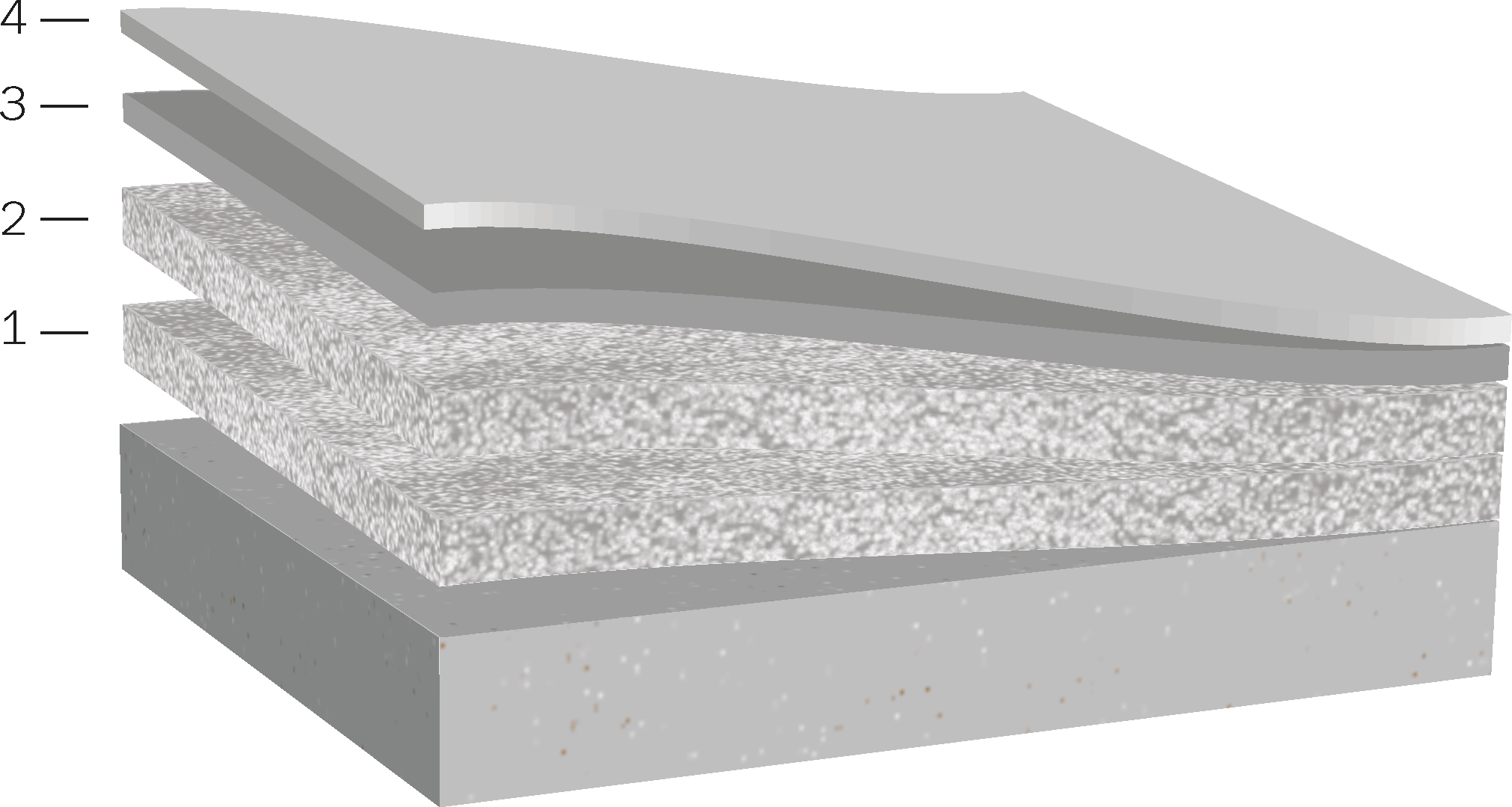

Novolac System Builds

Technical Documents

What areas of my facility are appropriate for this system?

Kitchens, bakeries, food processing, animal research, chemical storage rooms, and battery charging areas.

What are the limitations of the system?

Limited only by high levels of MVT (Moisture Vapor Transition). May be used with a Moisture Mitigating Primer when needed. When a great deal of Thermal Shock resistance is needed, please refer to Neocrete.

How can this system be used for recoating existing flooring systems?

May be applied over sound, high performance coating systems by sanding/abrading and patching any holes/cracks.

How long will the system last with daily use?

Three to five years, depending upon chosen system and utilizing appropriate aggregates.

What are the general recommendations for applying this system?

Surface profile of CSP3, squeegee/backroll and trowel, apply within system guidelines for each step.

You can trust Novolac in your next project

High-performance protection tested under the harshest environments. Novolac was developed to provide outstanding chemical, thermal shock, and impact resistance for industrial and institutional applications, including food processing, animal research, chemical rooms, and freezers.