Auto-Gard E is a high solids, low-odor hybrid system ideal for high volume, heavy traffic applications such as airports, retail and hospital garages. It provides a very tough, durable system that outperforms urethane systems in difficult service conditions.

Auto-Gard E

Two component, urethane/epoxy hybrid system with optional topcoats

System Overview

Auto-Gard E combines a urethane base coat with an epoxy wear coat, and a choice of epoxy or urethane topcoat. Designed for the toughest traffic, it utilizes our proven 70714/70715-09 epoxy or our 70750/70751 low-modulus epoxy for a wear coat that can handle the heavy traffic. A choice of our 7992-U aggregate or #16 aluminum oxide provides aggressive grip.

Our FC7540/FC7964 urethane or 70714/70715-09 epoxy may be selected for the topcoat, depending on UV exposure and other factors (consult with Neogard to determine the best option for your project). A variety of colors are available for both topcoats.

Use Area:

Vehicular Traffic, Heavy Duty

Type:

Urethane/Epoxy

Features:

- Epoxy wear coat

- Low modulus epoxy

- Epoxy wear coat

Benefits:

- Excellent aggregate retention

- Ideal for applications where stress relief and resistance to mechanical and thermal movement are required

- Higher performance in high torque areas such as turns and ramps

Selected Physical Properties

| Product | Description | Test Method | Results |

|---|---|---|---|

| Auto-Gard E system | Dynamic Coefficient of Friction | ANSI A137.1 | 0.83, dry surface, aluminum oxide aggregate |

| Auto-Gard E system | Dynamic Coefficient of Friction | ANSI A137.1 | 0.80, wet surface, aluminum oxide aggregate |

| Auto-Gard E system | Fire Resistance | ASTM E108 | Pass, with urethane topcoat |

| 70714/70715-09 topcoat | Taber Abrasion | ASTM D4060 | 61 mg/1,000 CS-17 |

| FC7540/FC7964 topcoat | Taber Abrasion | ASTM D4060 | 95 mg/1,000 CS-17 |

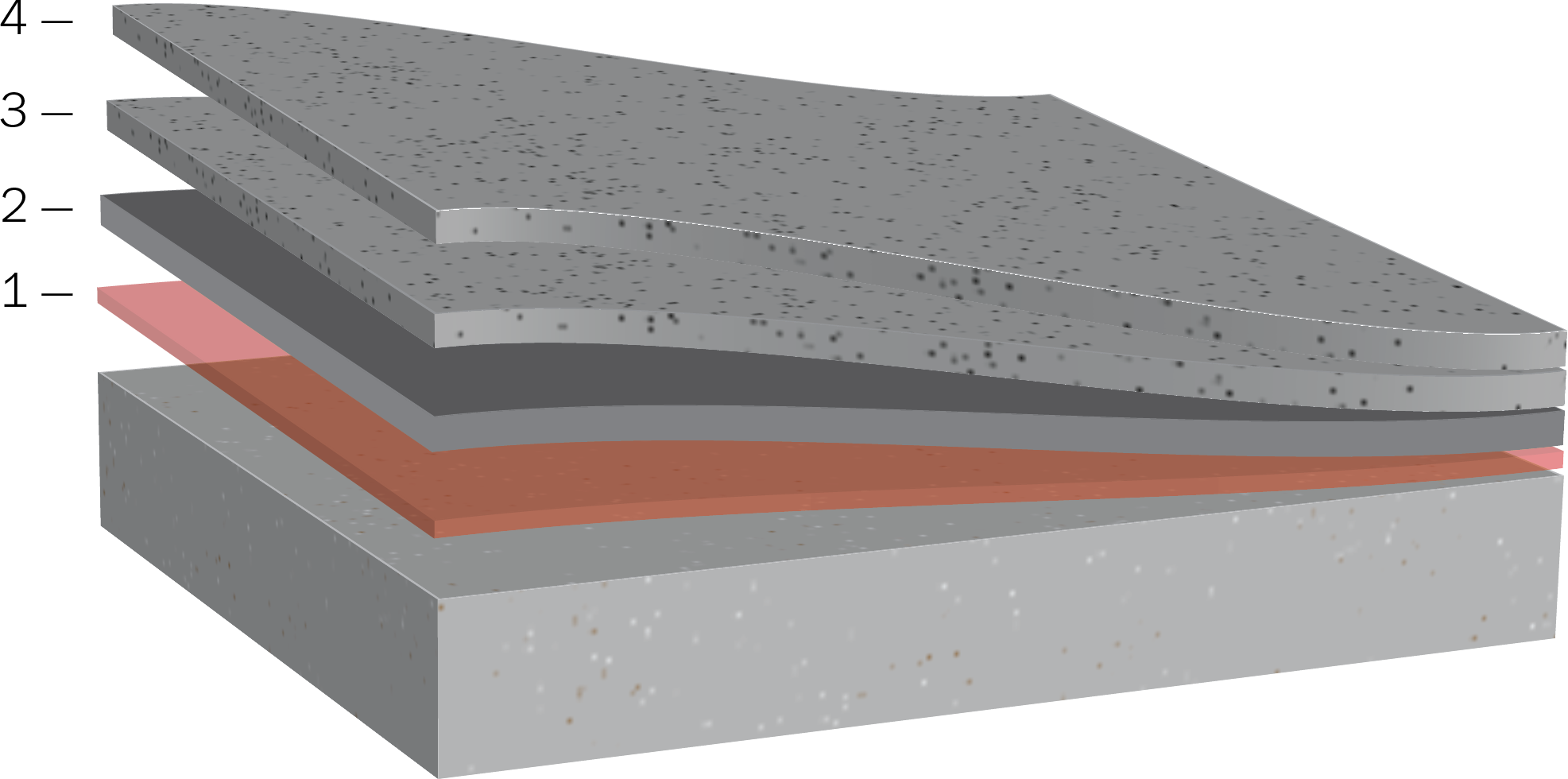

Auto-Gard E System Build

| Coat | Product | Coverage Rate | Mils WFT/DFT |

|---|---|---|---|

| 4 - Topcoat | 70714/70715-09 or FC7540/FC7964 (UV) |

110 sf/gal 100 sf/gal |

14/14 16/14 |

| 3 - HD Wear | 70750/70751 or 70714/70715-09 + 7992-U aggregate or #16 aluminum oxide |

100 sf/gal 100 sf/gal 10 lb/100 sf |

16/16 |

| or | |||

| 3 - Wear | 70750/70751 or 70714/70715-09 + 7992-U aggregate or #16 aluminum oxide |

133 sf/gal 133 sf/gal 15 lb/100 sf |

12/12 |

| 2 - Base | FC7500/FC7960 | 80 sf/gal | 20/20 |

| 1 - Primer | 7780/7781 7797/7798 |

300 sf/gal 300-500 sf/gal |

NA |

Technical Documents

How long does Auto-Gard E need to cure before opening to vehicular traffic?

Typically the coating needs to cure 72 hours before opening to vehicular traffic. In cooler temperatures this time may extend out as much as 24-36 hours.

What type concrete curing compounds can be used with Auto-Gard E?

It is best to water cure concrete or use a sodium silicate curing compound. The use of acrylic or other “film forming” compounds will create bond issues and must be removed.

What is the minimum temperature at which Auto-Gard E can be applied?

The coating should be applied at temperatures that are 40°F/4°C and rising during application.

What is the maximum concrete temperature that Auto-Gard E can be applied?

The coating should not be applied to deck surfaces that are =/> 100°F/38°C.

You can trust Auto-Gard E con your next project

High-performance protection tested under the harshest environments. Auto-Gard E was developed to endure intense vehicular traffic while providing a seamless, durable, skid-resistance membrane to prevent the ingress of moisture and chloride intrusion.