Neoflake and Neoflake RTS (Return To Service) systems create a vibrant, seamless and resilient flooring surface. They provide an exceptionally durable and long lasting floor while also looking great.

Neoflake

Thin film, 100% solids epoxy or polyaspartic systems with integral color flakes

System Overview

Innovacoatings Neoflake systems are visually appealing, high strength, slip resistant and abrasion resistant flooring systems. They are ideal for garage floors, commercial kitchens, locker rooms, sports venues, automotive showrooms and numerous other applications. These easy-to-clean systems can be customized to virtually any color blend.

Our standard Neoflake system utilizes our 70714/70715 and 70734/70735 epoxies. Neoflake RTS is a fast return-to-service system in two versions: Series 1 uses 70714/70715 as a primer and base coat, 70869/70819 Polyaspartic as seal coats, and random broadcast flakes; Series 2 is entirely composed of 70869/70819 Polyaspartic, and features flakes broadcast to full rejection.

Use Area:

Pedestrian Walkways, Automotive, Retail, Stadiums, Restaurants, Manufacturing

Type:

Epoxy/Polyaspartic

Features:

- Enhances appearance

- Economical

- Low VOC

- Easy to clean

- Slip resistant

Benefits:

- Customized color blends

- Seamless

- Anti-microbial

Selected Physical Properties

| Product | Description | Test Method | Results |

|---|---|---|---|

| 70734/70735 epoxy | Compressive Strength | ASTM D695 | 11,000 psi |

| 70817/70818 CRU | Taber Abrasion | ASTM D4060 | 23 mg/1,000 CS-17 |

| 70817/70818 CRU | Anti-Microbial | JIS Z 2801-2010 | Pass |

| 70869/70819 Polyaspartic | Taber Abrasion | ASTM | 55 mg/1,000 CS-17 |

| 70869/70819 Polyaspartic | Anti-Microbial | JIS Z 2801-2010 | Pass |

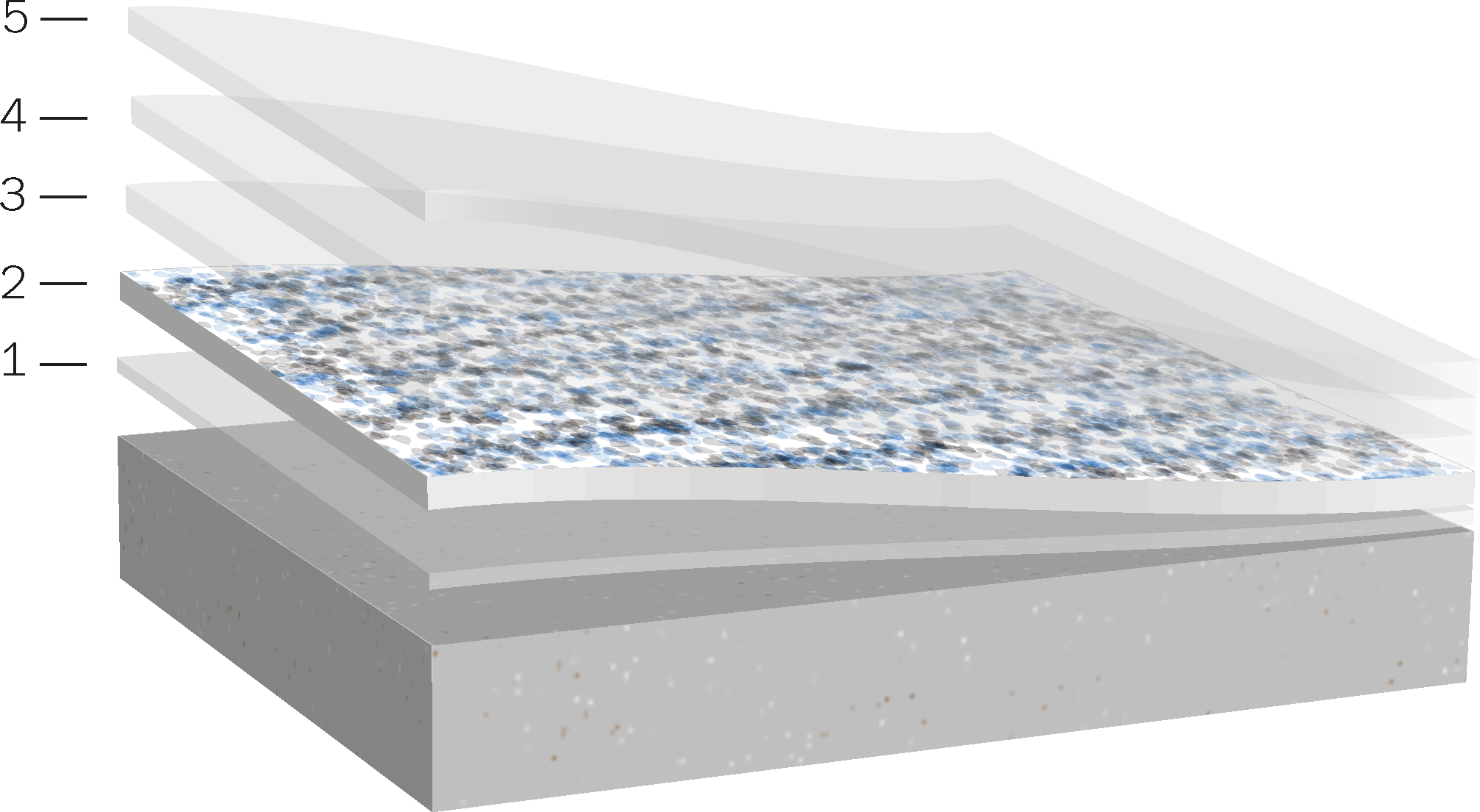

Neoflake System Build

| Coat | Product | Coverage Rate | Mils WFT/DFT |

|---|---|---|---|

| 6 - Optional Texture | 70734/70735 or 70817/70818 + 86500 Neogrip Spheres* |

400 sf/gal | 4/4 |

| 5 - 2nd Seal | 70734/70735 epoxy 70817/70818 CRU 70902/70910 urethane |

200 sf/gal | 8/8 |

| 4 - 1st Seal | 70734/70735 epoxy 70817/70818 CRU 70902/70910 urethane |

200 sf/gal | 8/8 |

| 3 - Aggregate | Color Flakes | Full Rejection | 16/16 |

| 2 - Base | 70714/70715 | 100 sf/gal | |

| 1 - Primer | 70714/70715 | 200 sf/gal | 8/8 |

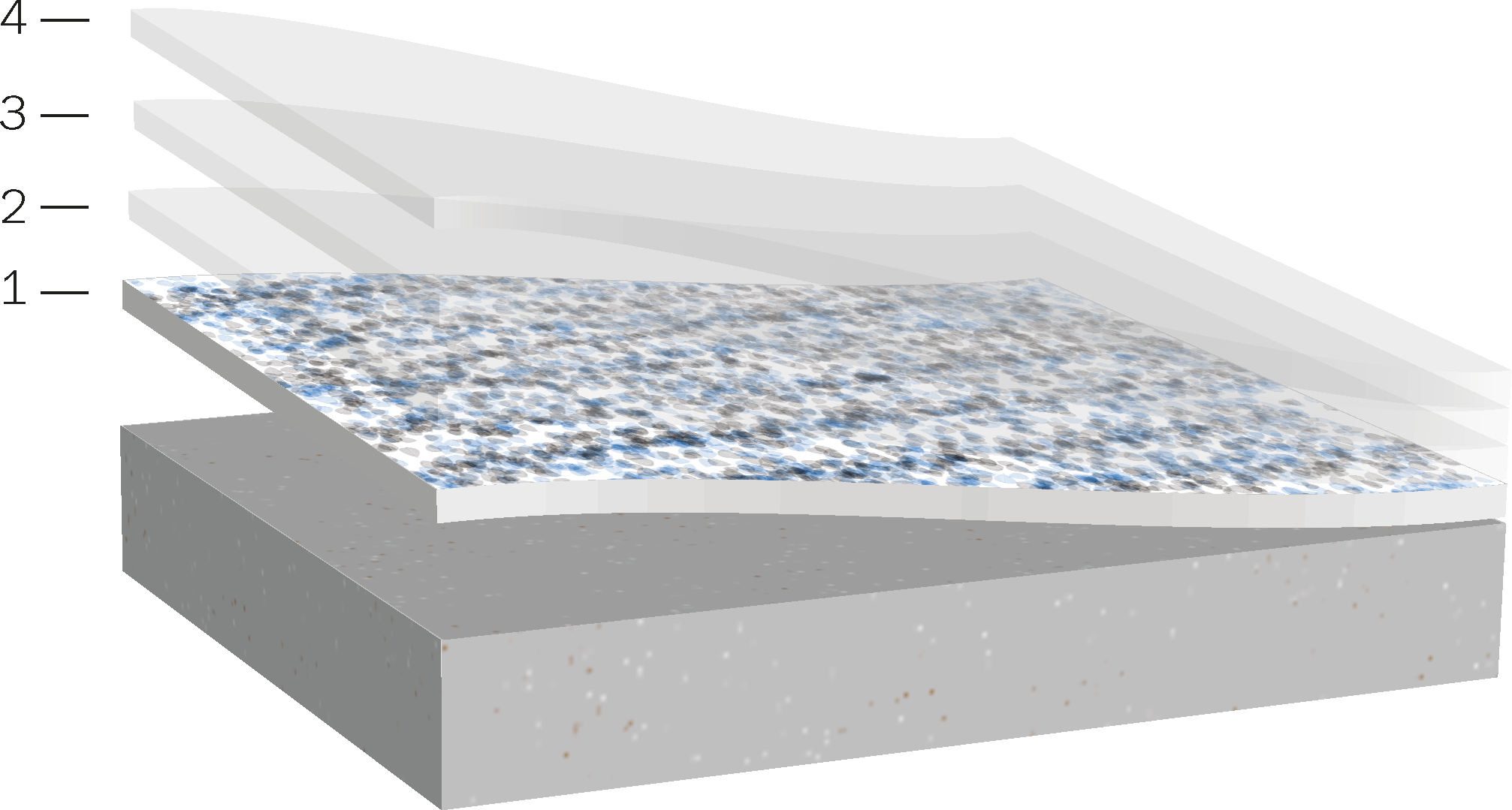

| Coat | Product | Coverage Rate | Mils WFT/DFT |

|---|---|---|---|

| 6 - Optional Texture | 70869/70819 Polyaspartic 86500 Neogrip Spheres* |

400 sf/gal | 4/4 |

| 5 - 2nd Seal | 70869/70819 Polyaspartic | 200 sf/gal | 8/8 |

| 4 - 1st Seal | 70869/70819 Polyaspartic | 200 sf/gal | 8/8 |

| 3 - Aggregate | Color Flakes | Desired coverage | 16/16 |

| 2 - Base | 70714/70715 | 100 sf/gal | |

| 1 - Primer | 70714/70715 | 200 sf/gal | 8/8 |

| Coat | Product | Coverage Rate | Mils WFT/DFT |

|---|---|---|---|

| 5 - Optional Texture | 70869/70819 Polyaspartic 86500 Neogrip Spheres* |

400 sf/gal | 4/4 |

| 4 - 2nd Seal | 70869/70819 Polyaspartic | 200 sf/gal | 8/8 |

| 3 - 1st Seal | 70869/70819 Polyaspartic | 200 sf/gal | 8/8 |

| 2 - Aggregate | Color Flakes | Full rejection | 16/16 |

| 1 - Base | 70869/70819 Polyaspartic | 100 sf/gal |

Technical Documents

What areas of my facility are appropriate for this system?

Decorative flake systems are appropriate for bathrooms, locker rooms, common areas, showroom floors, etc.

What are the limitations of the system?

May be used in conjunction with Moisture Mitigating Primer and not recommended for installation above 80% relative humidity.

How can this system be used for recoating existing flooring systems?

May be applied over sound, high performance coating systems by sanding/abrading and patching any holes/cracks.

How long will the system last with daily use?

3-5 years with normal abuse and wear. System is sustainable by sand/rebroadcast and topcoating.

What are the general recommendations for applying this system?

Surface prep of CSP3, squeegee/backroll, apply within system guidelines for each step.

You can trust Neoflake in your next project

High-performance protection tested under the harshest environments. Neoflake was developed for for garage floors, commercial kitchens, locker rooms, sports venues, automotive showrooms and numerous other applications. These easy-to-clean systems can be customized to virtually any color blend.