Neocrete systems are available with various topcoats and aggregates for any application, from industrial to decorative.

Neocrete

1/8” to 3/8” cementitious urethane flooring systems

System Overview

Innovacoatings Neocrete systems are cementitious polyurethane flooring systems ideal for use In kitchens, pharmaceutical, and food processing environments, including freezers and areas with high thermal cycling.

Innovacoatings has high impact, wear, and abrasion resistance which stands up to heavy machinery and equipment. Their exceptional chemical resistance and thermal shock tolerance exceeds requirements for flooring protection and cleanability. They have fast return to service allowing for shorter facility downtime, and the system can be installed in a wide range of temperatures and environments, including over quarry tile. Also meets South Coast AQMD VOC requirements.

See below for a list of available systems.

Use Area:

Commercial Kitchens, Food Processing/Packaging, Manufacturing Facilities, Pharmaceutical Production

Type:

Urethane Cement

Features:

- Fast turnaround

- Self-priming

- Easy to apply

- Resurfaces concrete

- Industrial and Decorative finishes available

Benefits:

- Resistant to thermal shock

- Anti-microbial system

- MVT Resistant

Selected Physical Properties

| Product | Description | Test Method | Results |

|---|---|---|---|

| Neocrete SL & RT | Compressive Strength | ASTM C579 | 7,700 psi |

| Neocrete SL & RT | Modulus of Elasticity | ASTM C580 | 446,700 psi |

| Neocrete SL & RT | Shore D | ASTM D2240 | 84 |

| Neocrete SL, RT, and Trowel | Resistance to Fungal Growth | ASTM G21 | No Support of Growth |

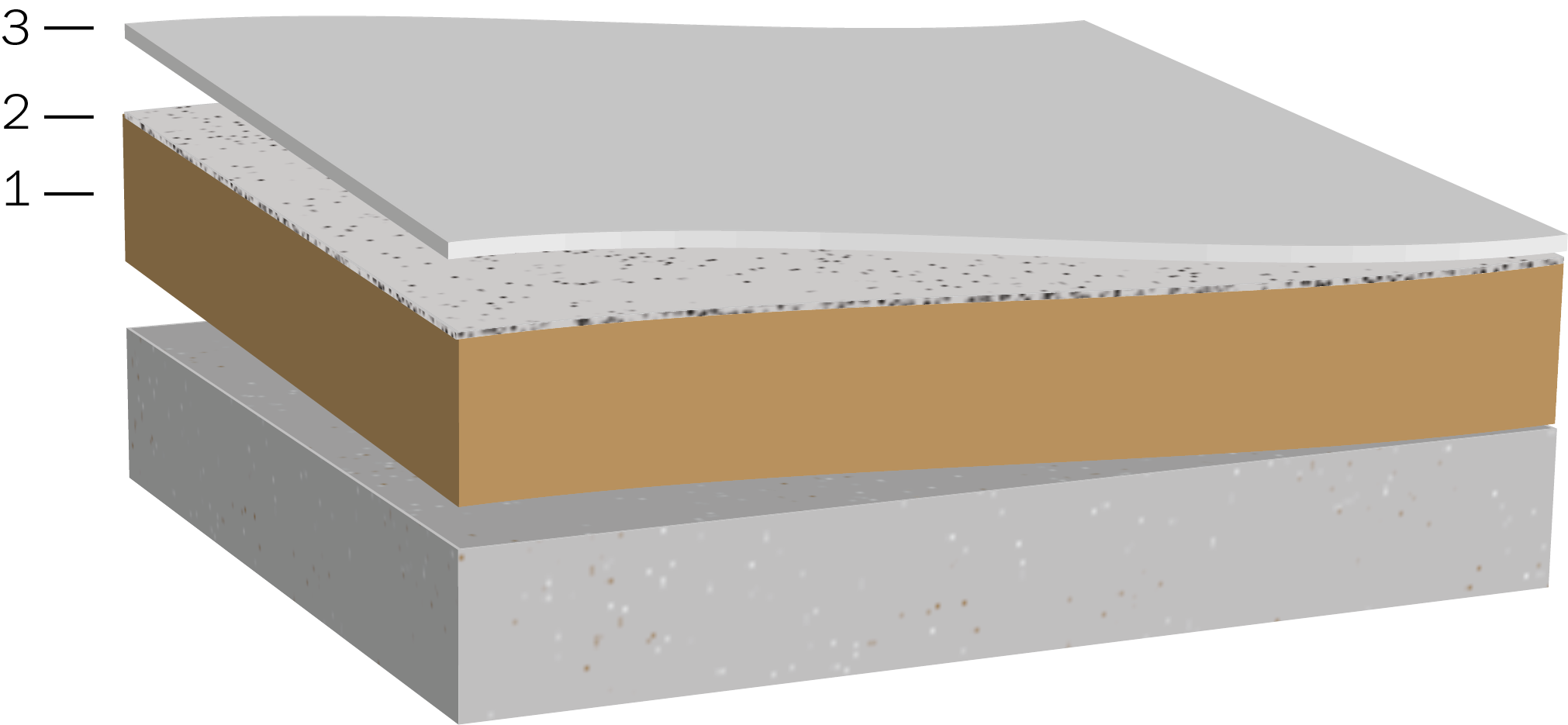

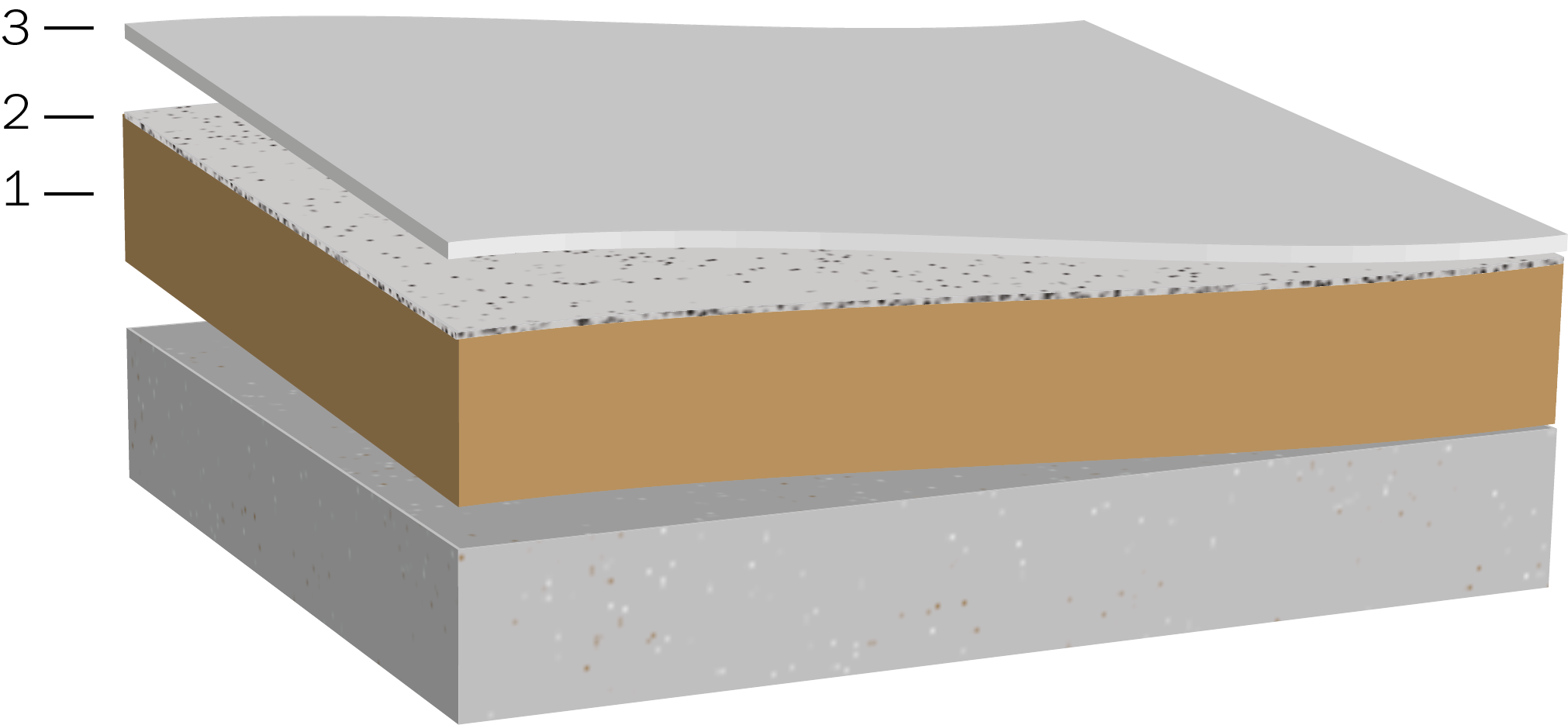

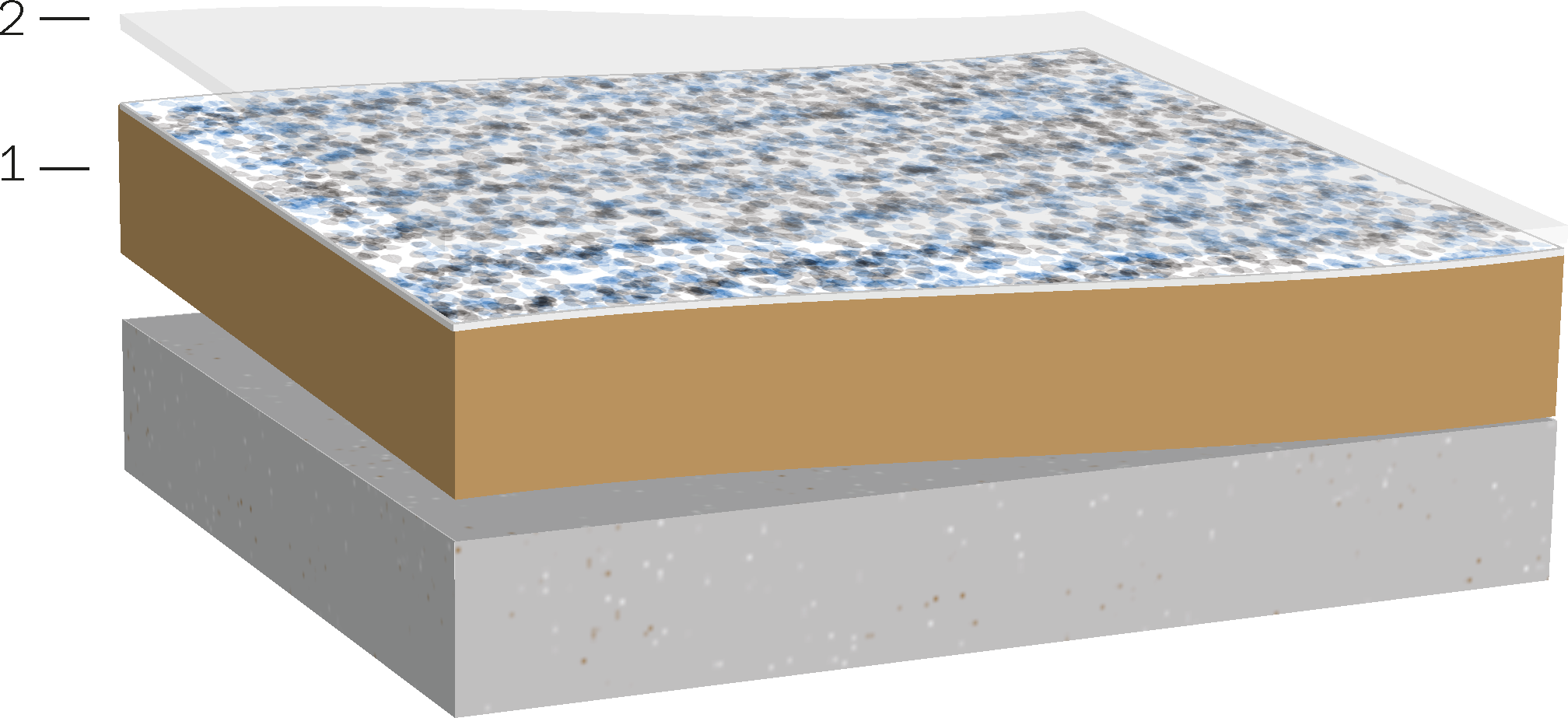

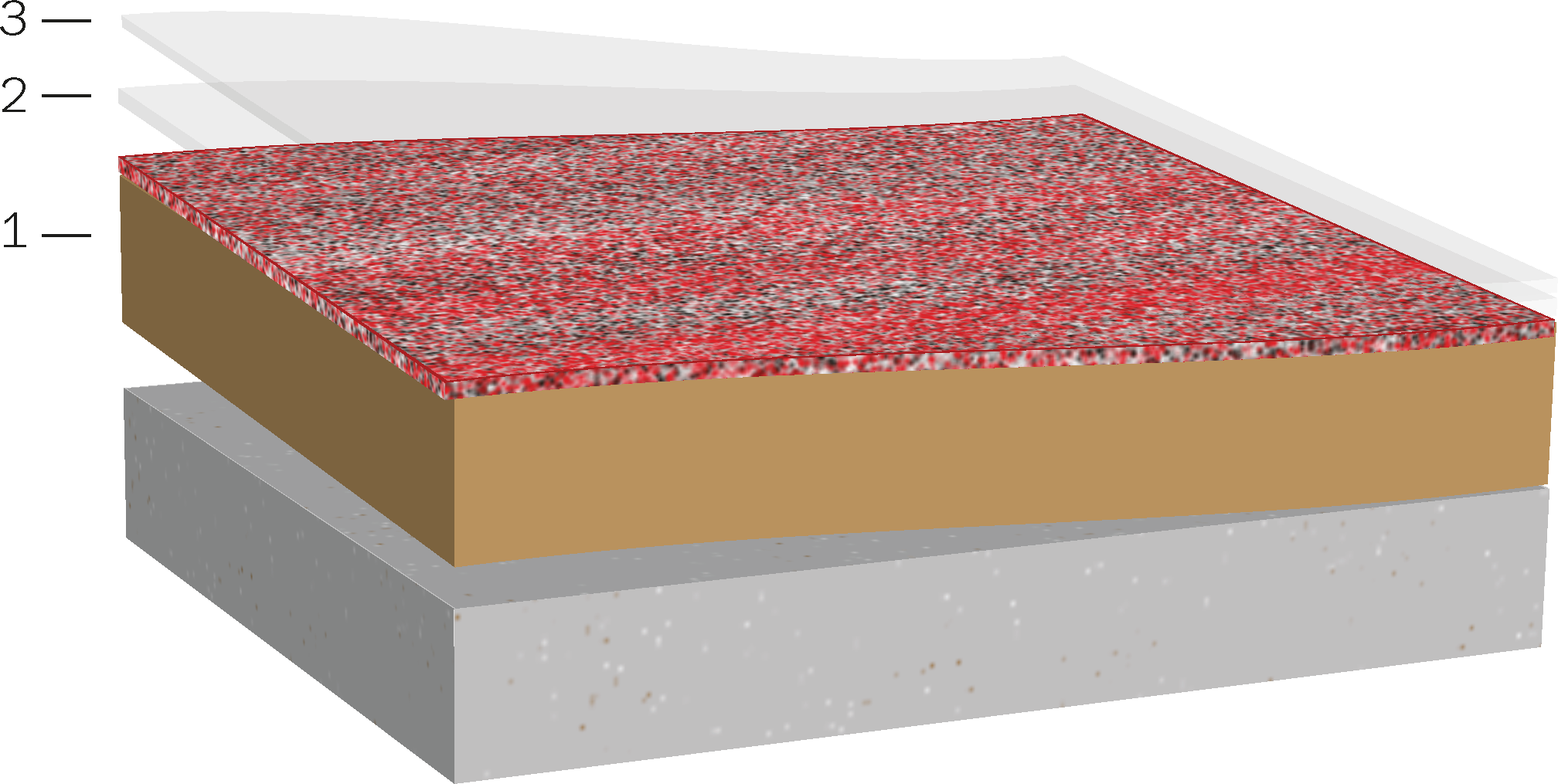

Neocrete System Builds

- RT (Rake-and-Trowel)

- RT Broadcast

- SL (Self-Leveling)

- SL Broadcast

- SL Flake (Decorative)

- SL Quartz (Decorative)

- Trowel

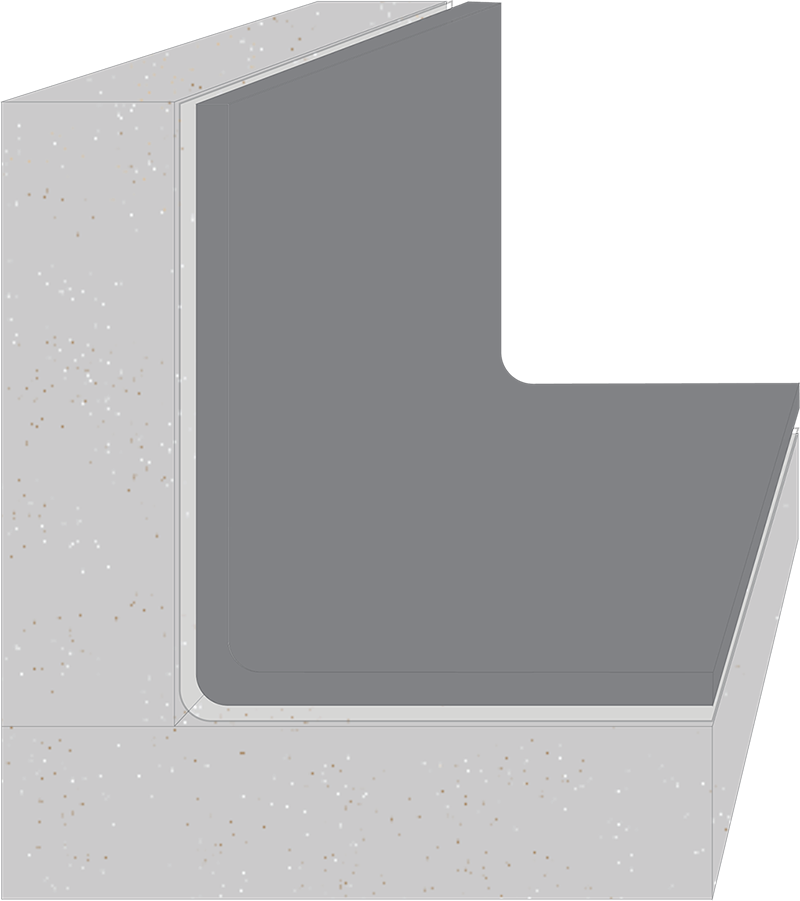

- V (Cove Base)

| Coat | Product | Coverage Rate | Mils WFT/DFT |

|---|---|---|---|

| 4 - 2nd Seal | 70869/70819 Polyaspartic | 200 sf/gal | 8/8 |

| 3 - 1st Seal | 70869/70819 Polyaspartic | 160 sf/gal | 10/10 |

| or | |||

| 4 - 2nd Seal | 70817/70818 CRU | 200 sf/gal | 8/8 |

| 3 - 1st Seal | 70817/70818 CRU | 160 sf/gal | 10/10 |

| 2 - Decorative Quartz | 187/187 (3/16") |

||

| 1 - Cementitious Polyurethane Mix |

70800 + 70801 + 70804 |

32 sf at 3/16" per mixed unit |

|

Technical Documents

What areas of my facility are appropriate for this system?

Food prep areas, food packaging, industrial kitchens, bathrooms where constant hot/cold water wash is utilized and thermal shock resistance is a must.

What are the limitations of the system?

Requires extra labor during mixing/application as system is very fast and capable of fast return to service.

How long will the system last with daily use?

5 years plus with constant use. System is functional and easily may be sustained with a sand/recoat of topcoat only after several years of abuse.

What are the general recommendations for applying this system?

Surface prep of CSP3-4, screed rake and trowel, apply within system guidelines for recoat of each step.

What markets is this system typically appropriate for?

Food/Beverage, Pharmaceutical, Healthcare, Restaurants, Stadiums.

How does this system hold up to thermal shock?

Mirrors expansion/contraction of concrete substrate thus superior thermal shock resistance compared to other generic flooring systems.

Does this system withstand high levels of moisture vapor?

Up to 25 pounds MVT per calcium chloride test.

You can trust Neogard Neocrete in your next project

High-performance protection tested under the harshest environments. Neogard Neocrete systems are cementitious polyurethane flooring systems ideal for use in kitchens, pharmaceutical, and food processing environments, including freezers and areas with high thermal cycling.