KitchenGard 3/16” addresses the need for food processing, industrial kitchens, or other areas where protection from elevated temperature, abrasion, impact, and chemicals is required.

KitchenGard

100% solids, high-performance epoxy slurry broadcast system finished with novolac epoxy

System Overview

KitchenGard 3/16”, as its name suggests, is tailored for the challenging conditions found in commercial kitchens and food processing operations. It uses a 70714/70715 epoxy slurry base with 70704/70705 Novolac epoxy topcoats to create a system that can handle thermal shock and aggressive chemicals. It also features excellent abrasion and heavy-duty impact resistance.

Use Area:

Commercial Kitchens, Manufacturing Facilities

Type:

Epoxy

Features:

- Epoxy slurry broadcast system provides resurface of concrete

- May be smooth, stipple or texture finish

Benefits:

- Extreme compressive strength

- Provides higher temperature resistance compared to traditional epoxy

- Easy to clean

- Improved light reflectance

Selected Physical Properties

| Product | Description | Test Method | Results |

|---|---|---|---|

| 70704/70705 Novolac | Compressive Strength | ASTM D695 | 10,000 psi |

| 70704/70705 Novolac | Modulus of Elasticity | ASTM D790 | 134,000 psi |

| 70704/70705 Novolac | Shore D | ASTM D2240 | 84 |

| 70704/70705 Novolac | Taber Abrasion | ASTM D4060 | 40 mg/1,000 CS-17 |

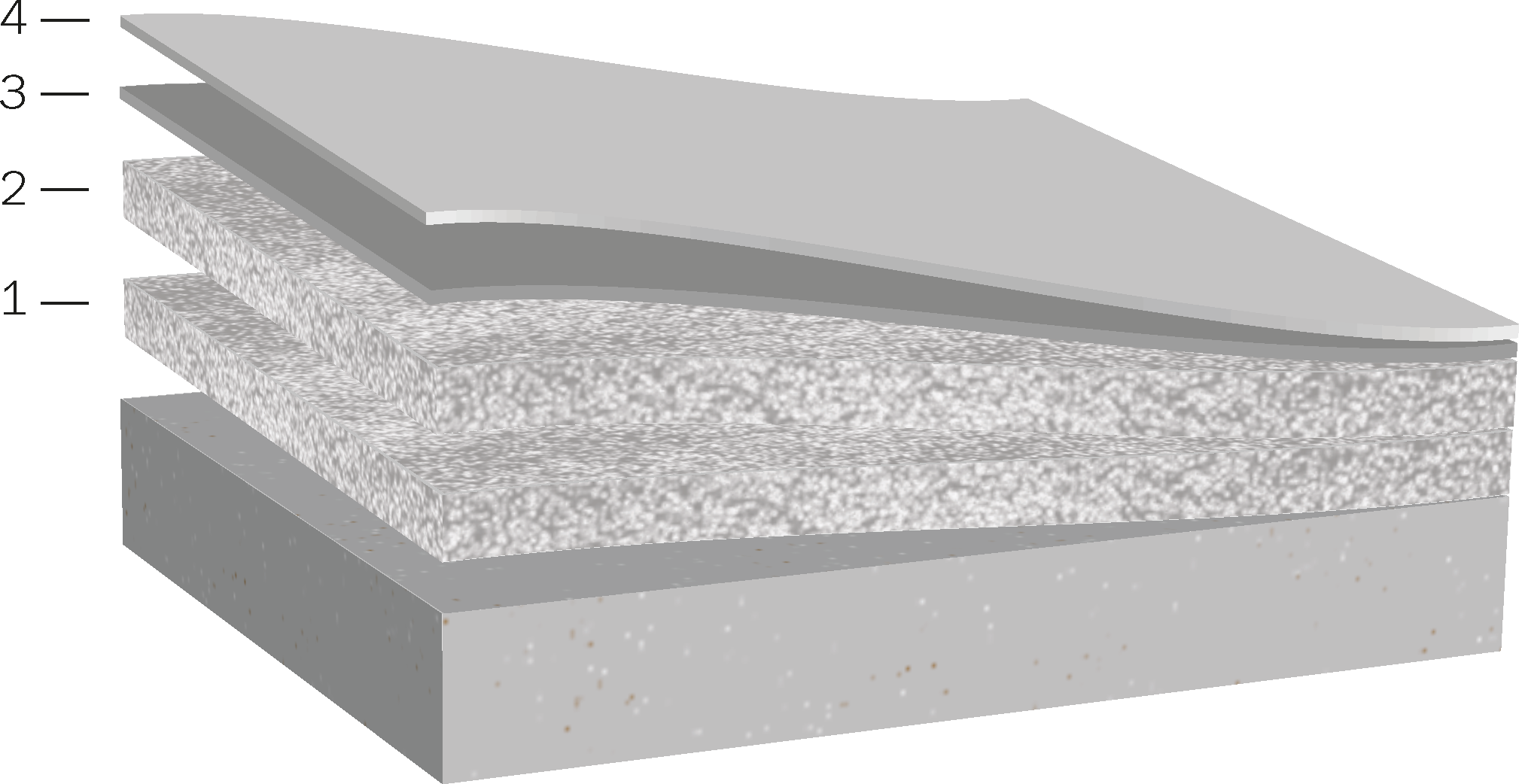

KitchenGard 3/16" System Build

| Coat | Product | Coverage Rate | Mils WFT/DFT |

|---|---|---|---|

| 4 - 2nd Seal | 70704/70705 | 200 sf/gal | 8/8 |

| 3 - 1st Seal | 70704/70705 | 200 sf/gal | 8/8 |

| 2 - 2nd Slurry Base | 70714/70715 + 86468 flour + 86364 sand aggregate |

40 sf/gal Mix 1:1 w/epoxy 100 lbs/100 sf |

40/40 |

| 1 - 1st Slurry Base | 70714/70715 + 86468 flour + 86364 sand aggregate |

40 sf/gal Mix 1:1 w/epoxy 100 lbs/100 sf |

40/40 |

Technical Documents

What areas of my facility are appropriate for this system?

Kitchen and food prep areas without a great deal of thermal shock. Daily cleaning with tap water and biodegradable cleaners is appropriate.

What are the limitations of the system?

Limited only by high levels of MVT(Moisture Vapor Transition). May be used with a Moisture Mitigating Primer when needed.

How long will the system last with daily use?

3-5 years depending upon chosen system and utilizing different appropriate topcoats.

What are the general recommendations for applying this system?

Surface prep of CSP3, squeegee/backroll or trowel, apply within system guidelines for each step.

What markets is this system typically appropriate for?

Restaurants, commercial kitchens, wineries, grocery stores.

You can trust KitchenGard in your next project

High-performance protection tested under the harshest environments. KitchenGard was developed for the challenging conditions found in commercial kitchens and food processing operations. It also features excellent abrasion and heavy-duty impact resistance.