CG Series flooring systems are fully customizable, high performance coating systems, designed for the demands of industrial and commercial facilties.

CG Series

100% solids, high performance epoxy systems from thin film to 1/4” applications

System Overview

CG Series systems permit concrete floors to be seamlessly resurfaced utilizing specialized components needed for long-lasting peak performance in virtually any environment. Whether a concrete floor must tolerate heavy foot traffic, large equipment, or harsh chemicals, CG Series systems are tailored to accommodate these different needs, resulting in an easy-to-maintain, seamless floor that is resistant to abrasion, aggressive chemicals and heavy-duty impact.

A variety of colors, surface textures and gloss levels provide customers with the flexibility of specifying the optimal CG Series system to improve light reflectance, durability and overall facility aesthetics.

Use Area:

Manufacturing, Institutional, Commercial

Type:

Epoxy w/optional topcoats

Features:

- Thin film-1/4” coating systems

- Fully customizable system thickness

- May be used for recoating existing systems

- Optional textures available

Benefits:

- Customizable cost savings

- Improves light reflectance

- Improves cleanability

Selected Physical Properties

| Product | Description | Test Method | Results |

|---|---|---|---|

| 70817/70818 clear/tinted CRU | Shore D | ASTM D2240 | 70 |

| 70817/70818 clear/tinted CRU | Taber Abrasion | ASTM D4060 | 23 mg/1,000 CS-17 |

| 70817/70818 clear/tinted CRU | Anti-Microbial | JIS Z 2801-2010 | Pass |

| 70714/70715 epoxy | Compressive Strength | ASTM D695 | 25,300 psi |

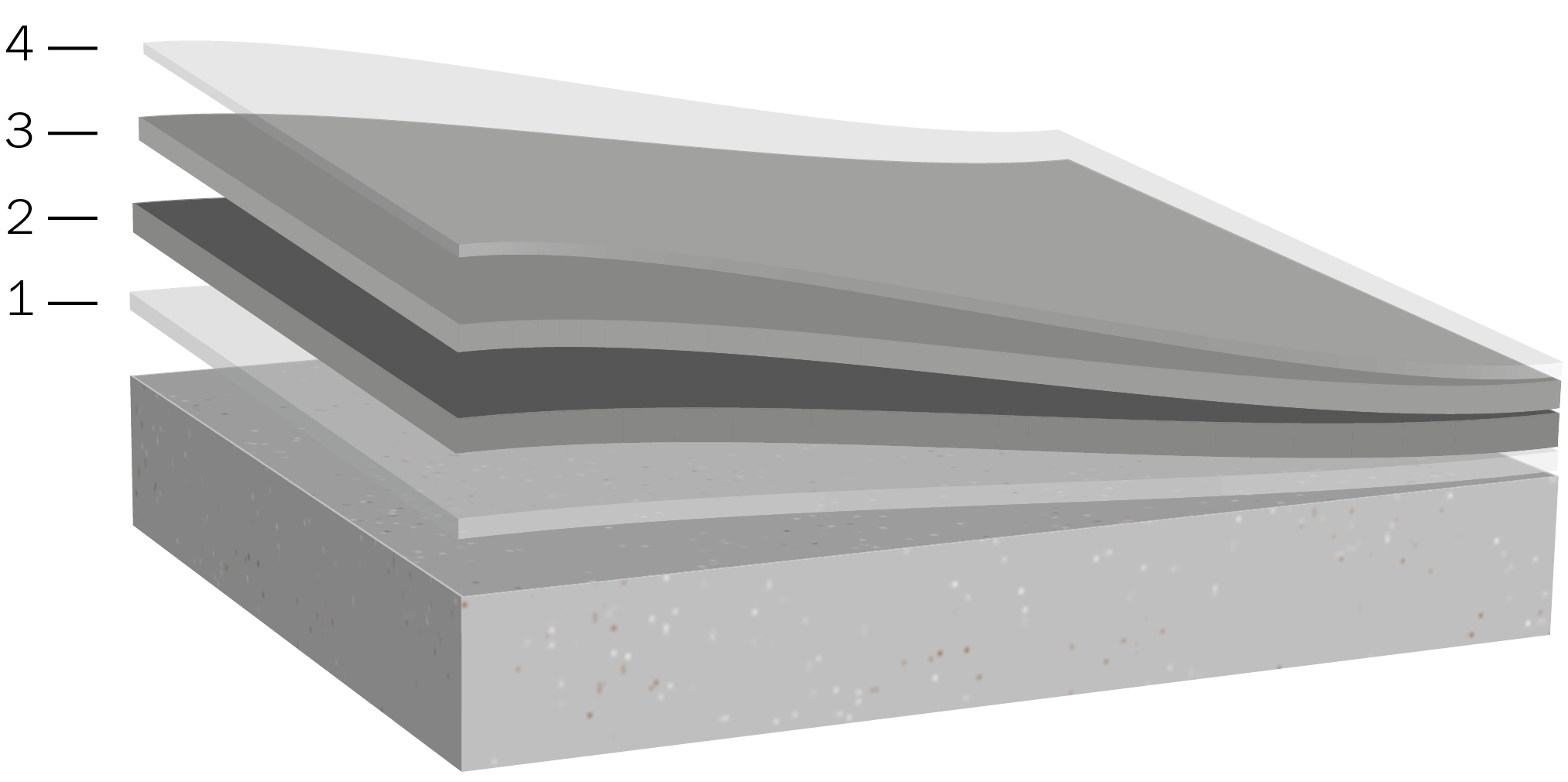

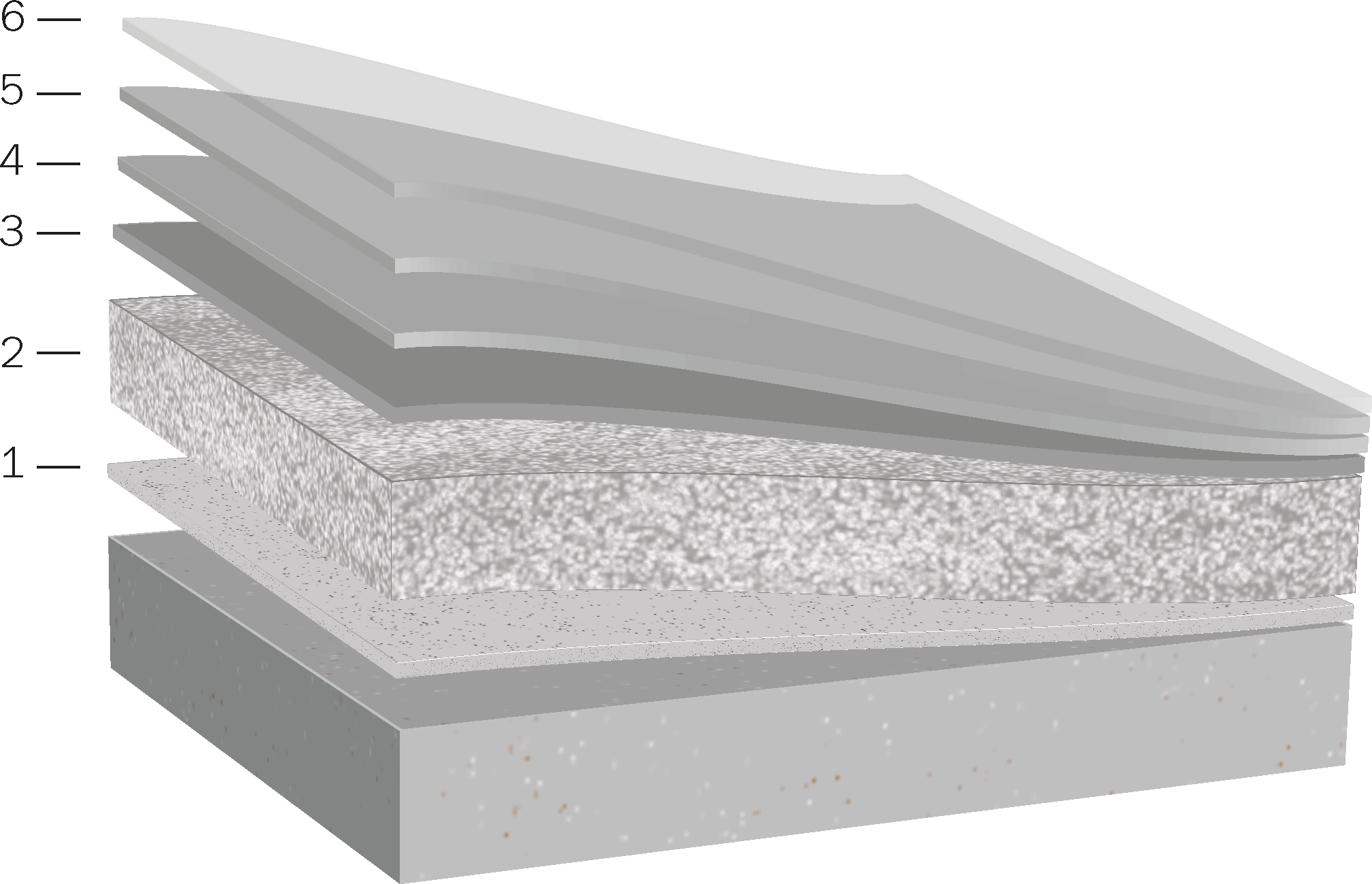

CG Series System Build

| Coat | Product | Coverage Rate | Mils WFT/DFT |

|---|---|---|---|

| 5 - Optional Texture | 70714/70715 or 70817/70818 + 86500 Neogrip Spheres* |

400 sf/gal | 4/4 |

| 4 - Optional Chem/ UV Resistant |

70817/70818 | 200 sf/gal | 8/8 |

| 3 - Topcoat | 70714/70715 | 130 sf/gal | 12/12 |

| 2 - Base | 70714/70715 | 130 sf/gal | 12/12 |

| 1 - Primer | 70714/70715 | 200 sf/gal | 8/8 |

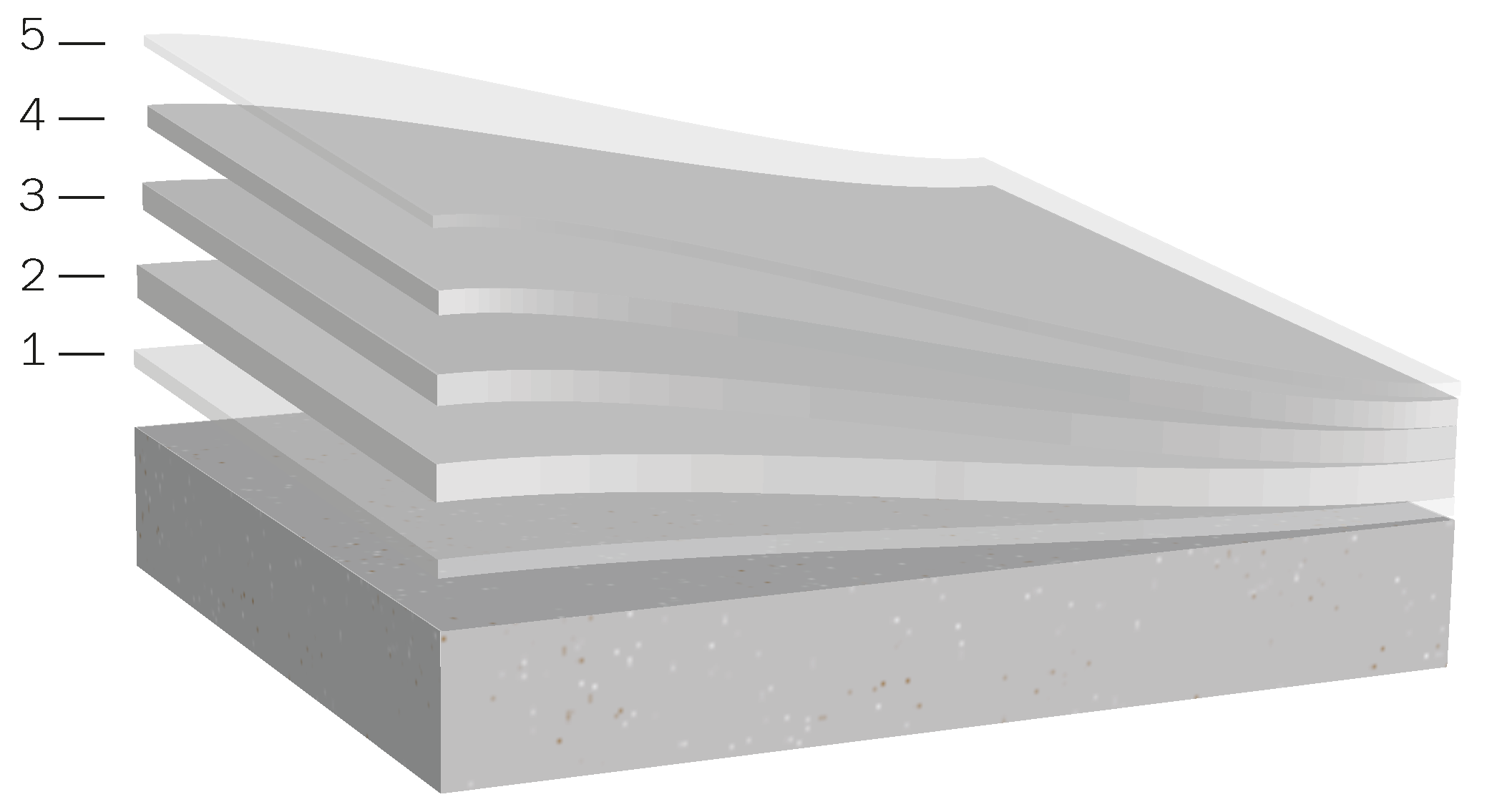

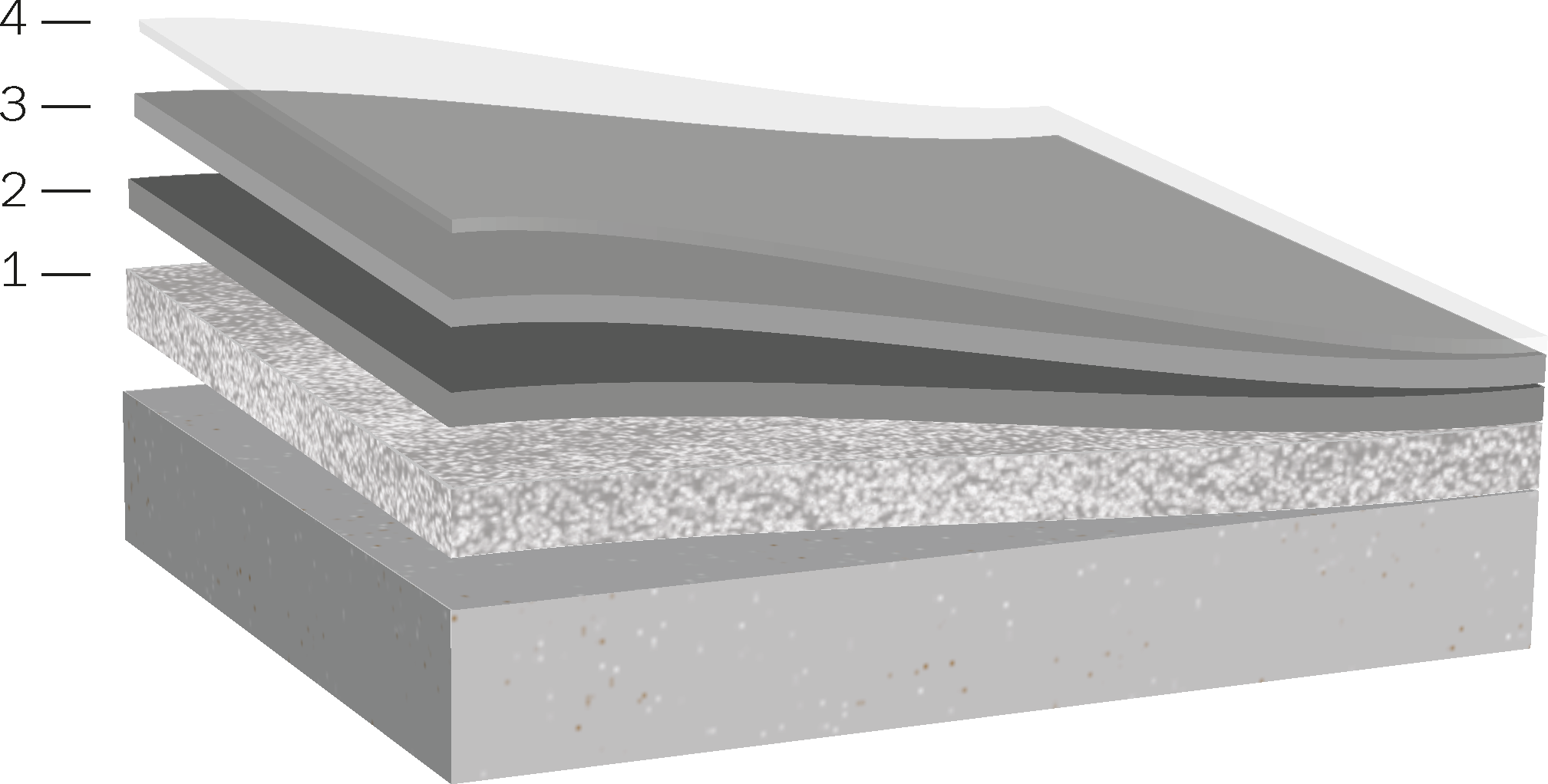

| Coat | Product | Coverage Rate | Mils WFT/DFT |

|---|---|---|---|

| 5 - Optional Chem/ UV Resistant |

70817/70818 | 400 sf/gal | 4/4 |

| 4 - 2nd Seal | 70714/70715 | 200 sf/gal | 8/8 |

| 3 - 1st Seal | 70714/70715 | 160 sf/gal | 10/10 |

| 2 - 2nd Base | 70714/70715 + 86364 sand aggregate |

80 sf/gal 50 lbs/100 sf |

20/20 |

| 1 - 1st Base | 70714/70715 + 86364 sand aggregate |

80 sf/gal 50 lbs/100 sf |

20/20 |

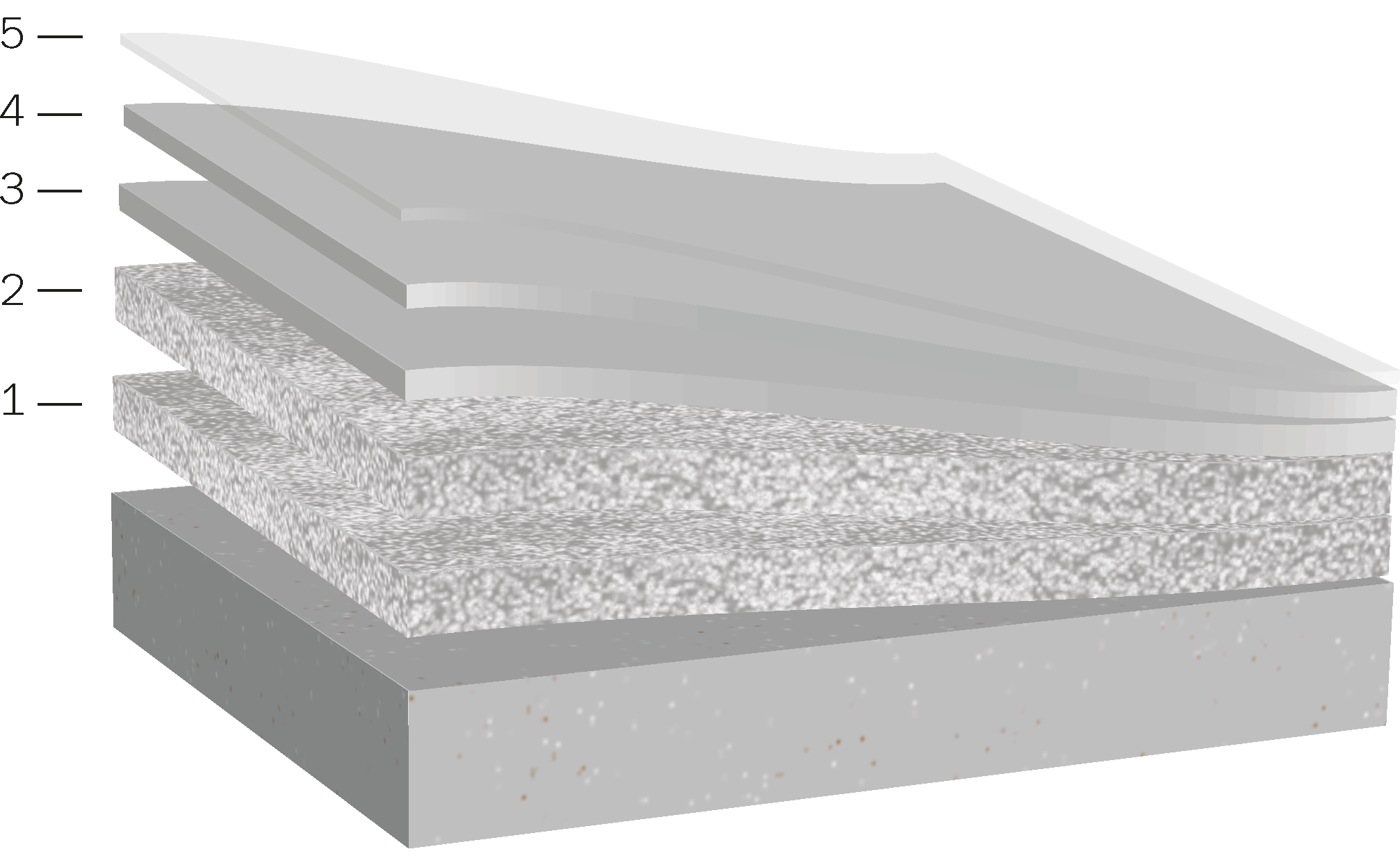

| Coat | Product | Coverage Rate | Mils WFT/DFT |

|---|---|---|---|

| 6 - Optional Chem/ UV Resistant |

70817/70818 | 400 sf/gal | 4/4 |

| 5 - 2nd Seal | 70714/70715 | 200 sf/gal | 8/8 |

| 4 - 1st Seal | 70714/70715 | 200 sf/gal | 8/8 |

| 3 - Grout | 70714/70715 | 200 sf/gal | 8/8 |

| 2 - Mortar | 70714/70715 + 67CUS99980 CG Epoxy Mortar Blend |

Specified Thickness | |

| 1 - Primer | 70714/70715 + 67CUS99980 CG Epoxy Mortar Blend |

200 sf/gal 20 lbs/100 sf |

8/8 |

Technical Documents

What areas of my facility are appropriate for this system?

All areas with foot and fork lift traffic depending upon weight and type of use. Bathrooms, office, warehouse, production and common areas included.

What are the limitations of the system?

Limited only by high levels of MVT(Moisture Vapor Transition). May be used with a Moisture Mitigating Primer when needed. Highly customizable depending upon desired texture and cleaning procedures.

How can this system be used for recoating existing flooring systems?

May be applied over sound, high performance coating systems by sanding/abrading and patching any holes/cracks.

How long will the system last with daily use?

3-5 years depending upon chosen system and utilizing different appropriate topcoats.

What are the general recommendations for applying this system?

Surface prep of CSP3, squeegee/backroll and trowel, apply within system guidelines for each step.

You can trust CG Series in your next project

High-performance protection tested under the harshest environments. CG Series systems are tailored to accommodate these different needs, resulting in an easy-to-maintain, seamless floor that is resistant to abrasion, aggressive chemicals and heavy-duty impact.