Auto-Gard offers excellent performance properties to provide outstanding adhesion, crack bridging, and abrasion resistance. On the market for over 40 years, it has a solid track record of protecting concrete structures.

Auto-Gard

System Overview

Auto-Gard is a proven waterproofing system for concrete parking decks and pedestrian high-traffic applications, especially stadiums. Auto-Gard provides a seamless, durable, skid-resistant membrane, preventing ingress of moisture and chloride intrusion that lead to premature deterioration.

Maintain the structural integrity and appearance of your investments with Auto-Gard, and prolong the lifecycle of your structure while reducing cost over time with proper maintenance.

Use Area:

Vehicular Traffic

Type:

Urethane

Features:

- Single component

- Elastomeric properties throughout system

- Reduced application steps

Benefits:

- Reduced mixing time

- Aids in crack bridging

- Allows for increased production

Selected Physical Properties

| Product | Description | Test Method | Results |

|---|---|---|---|

| Auto-Gard system | Dynamic Coefficient of Friction | ANSI A137.1 | 0.78, dry surface |

| Auto-Gard system | Dynamic Coefficient of Friction | ANSI A137.1 | 0.54, wet surface |

| Auto-Gard system | Fire Resistance | ASTM E108 | Pass |

| Auto-Gard system | Standard Specifications | ASTM C957 | Exceeds requirements |

| 7430 topcoat | Taber Abrasion | ASTM D4060 | 25 mg/1,000 CS-17 |

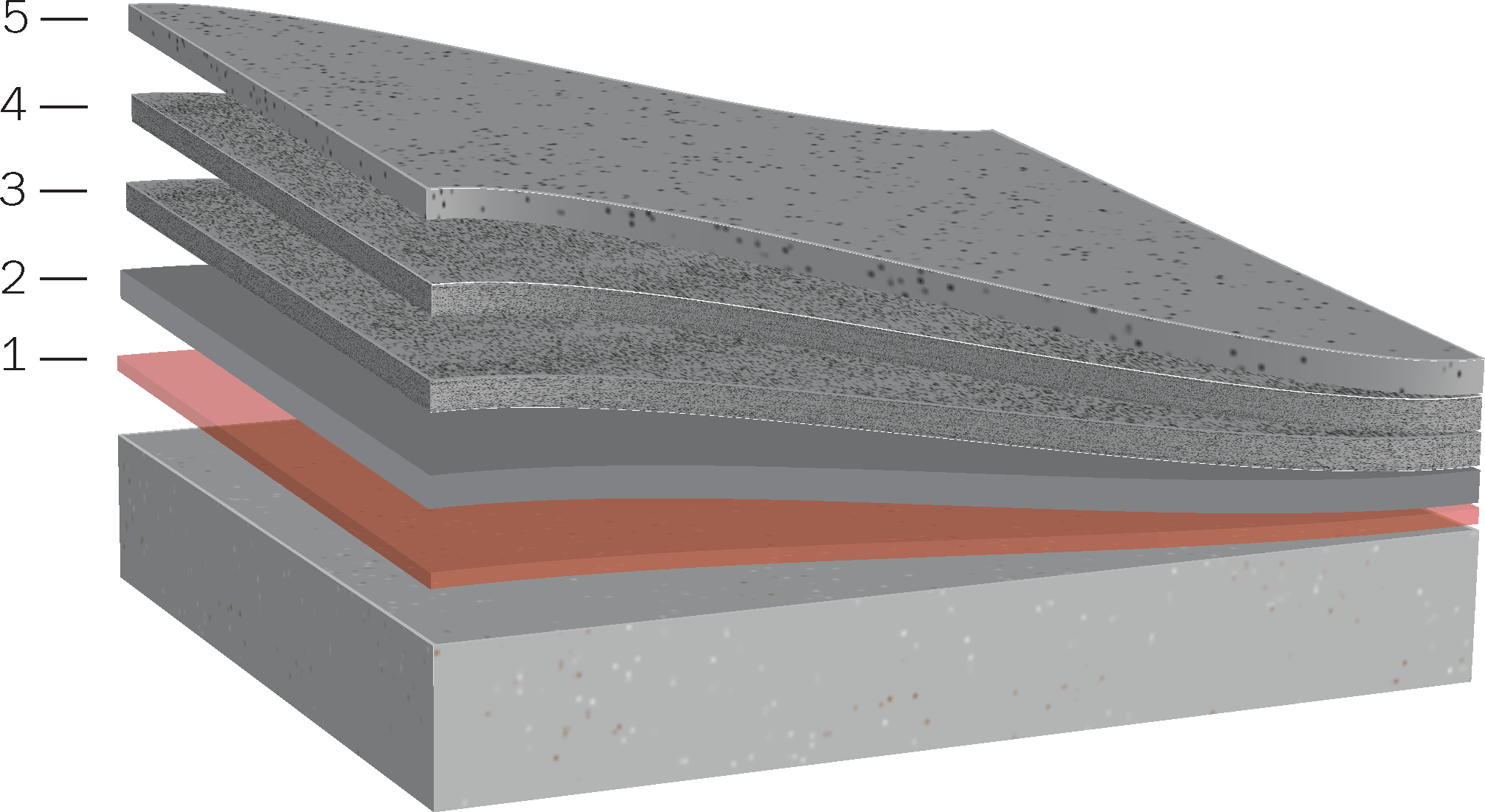

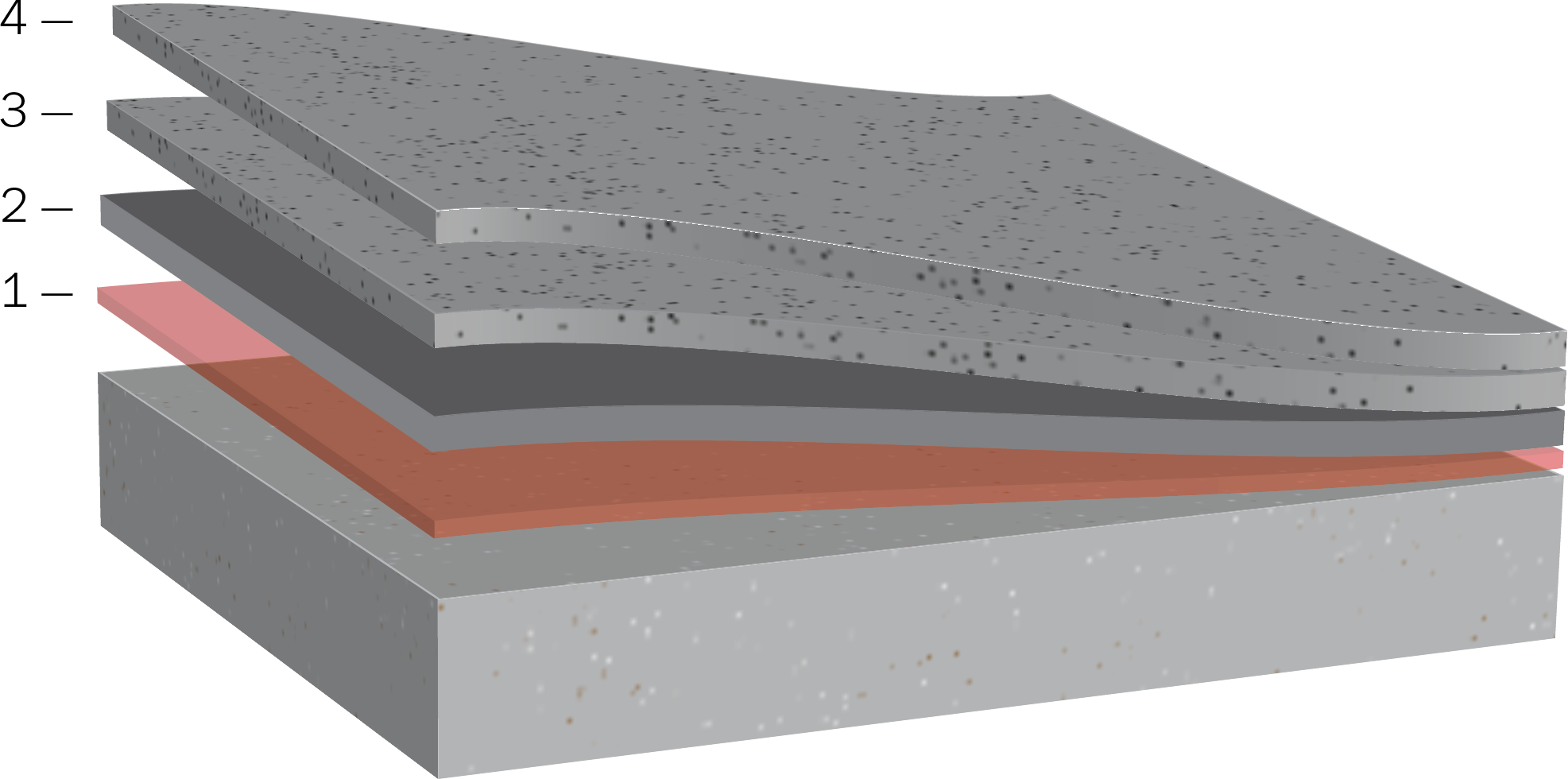

Auto-Gard System Build

| Coat | Product | Coverage Rate | Mils WFT/DFT |

|---|---|---|---|

| 5 - Topcoat | 7430 series | 100 sf/gal | 16/12 |

| 4 - HD Wear | 7430 series + 7992 aggregate |

100 sf/gal 10 lb/100 sf |

16/12 |

| 3 - Wear | 7430 series + 7992 aggregate |

150 sf/gal 15 lb/100 sf |

10/8 |

| 2 - Base | 70410 | 60 sf/gal | 26/20 |

| 1 - Primer | 7760/7761 7780/7781 7797/7798 |

300 sf/gal |

NA |

Technical Information

Descargas

Documentación

How often do I need to maintain epoxy floors?

Innovacoatings recommends washing all floors at least once a week, and high-traffic areas daily, using the proper brush and detergent. Areas in which oil and grease are prevalent will also require daily attention.

Do epoxy floors scratch easily?

Epoxy flooring doesn’t scratch easily due to it being a hard resin coating, however like any surface if something sharp enough scratches the surface, scratches may appear.

How long until you can walk on an epoxy floor?

Once the epoxy has completely cured, it is safe to step on. If using 100% solids epoxy, your floor will be cured and walkable in about 12 – 18 hours. You can return to full heavy traffic after about 36 – 72 hours. Most epoxies reach full chemical cure within 7 days of application.